The 4L60E transmission is a widely used GM automatic transmission, known for durability and versatility. This guide focuses on its wiring diagram for manual shift conversions.

1.1 Overview of the 4L60E Transmission

The 4L60E is a 4-speed automatic transmission developed by General Motors, widely used in trucks and SUVs due to its durability and versatility. It features an electronically controlled system managed by a Transmission Control Module (TCM), which optimizes shift points and torque delivery. The transmission is known for its robust design and ability to handle heavy-duty applications. Its wiring diagram is essential for understanding connections between components like the TCM, solenoid pack, and sensors, ensuring proper functionality. This guide focuses on the wiring aspects, particularly for manual shift conversions, to enhance performance and control.

1.2 Importance of Manual Shift Wiring Diagrams

Manual shift wiring diagrams are crucial for understanding and implementing a manual shift conversion on the 4L60E transmission. They provide a detailed layout of electrical connections, ensuring proper communication between components like the TCM, solenoids, and sensors. These diagrams are essential for troubleshooting issues such as erratic shifting or loss of manual control. By following the wiring diagram, enthusiasts can safely and accurately install manual shift components, optimizing performance and reliability. It serves as a blueprint for achieving precise control over the transmission’s operation, making it indispensable for both installation and maintenance.

Key Components of the 4L60E Manual Shift Wiring

The 4L60E manual shift wiring system includes essential components like the TCM, solenoid pack, PCS, TPS, VSS, and manual shift selector, ensuring precise transmission control and functionality.

2.1 Transmission Control Module (TCM)

The Transmission Control Module (TCM) is the brain of the 4L60E manual shift wiring system, responsible for processing sensor data and controlling shift patterns. It interprets signals from the Throttle Position Sensor (TPS) and Vehicle Speed Sensor (VSS) to determine optimal shifting points. The TCM communicates with the solenoid pack to activate hydraulic pressure changes, ensuring smooth manual shifts. Proper wiring connections to the TCM are critical for accurate transmission control. Any issues with the TCM or its wiring can lead to erratic shifting or complete loss of manual shift functionality. Regular diagnostic checks are essential to maintain its performance.

2.2 Solenoid Pack and Valve Body

The solenoid pack and valve body are critical components in the 4L60E manual shift wiring system. The solenoid pack receives electrical signals from the TCM, controlling hydraulic pressure within the valve body. This pressure regulates gear shifts, ensuring smooth transitions between manual modes. The valve body houses the solenoids and directs fluid flow to engage clutches and bands. Proper wiring connections between the TCM and solenoid pack are essential for accurate shift control. Any malfunction in these components can lead to erratic shifting or loss of manual control, emphasizing the importance of precise installation and maintenance.

2.3 Pressure Control Solenoid (PCS)

The Pressure Control Solenoid (PCS) is a key component in the 4L60E manual shift wiring system, regulating hydraulic line pressure within the transmission. Controlled by the TCM, the PCS adjusts pressure based on input from the TPS and VSS. Proper wiring ensures precise control over shift timing and firmness. Incorrect wiring or a faulty PCS can lead to erratic shifting, slipping, or delayed engagements. Regular maintenance and diagnostic checks are crucial to maintain optimal performance and prevent premature wear on transmission components.

2.4 Throttle Position Sensor (TPS)

The Throttle Position Sensor (TPS) plays a critical role in the 4L60E manual shift wiring system by providing real-time throttle position data to the Transmission Control Module (TCM). Accurate TPS signals ensure proper shift timing, torque converter engagement, and line pressure adjustments. The TPS is typically wired to the TCM via a 5V reference circuit, signal, and ground wires. Incorrect wiring or a faulty TPS can lead to erratic shifting, poor engine performance, or transmission slipping. Proper calibration and wiring of the TPS are essential for smooth manual shift functionality and optimal transmission operation.

2.5 Vehicle Speed Sensor (VSS)

The Vehicle Speed Sensor (VSS) is a critical component in the 4L60E manual shift wiring system, providing the Transmission Control Module (TCM) with accurate vehicle speed data. This data is essential for determining proper shift points, torque converter engagement, and line pressure adjustments. The VSS is typically located on the transmission’s output shaft and wired to the TCM using a 5V reference, signal, and ground circuit. A faulty or incorrectly wired VSS can cause erratic shifting, slipping, or harsh engagement. Proper installation and wiring of the VSS are vital for smooth manual shift operation and overall transmission performance.

2.6 Manual Shift Selector and Cable

The manual shift selector and cable are essential for controlling the 4L60E transmission in manual mode. The selector, typically mounted on the shift lever, sends mechanical input to the transmission via the cable. Proper installation involves routing the cable from the selector to the transmission’s manual shaft, ensuring it’s securely fastened with a locking clip. The cable must be adjusted to prevent slack or tension, which can cause inaccurate shifting. Correct routing and adjustment are crucial for smooth, precise gear changes. Always refer to the wiring diagram for specific connection points and ensure the cable is properly seated to avoid mechanical issues during operation.

Tools and Materials Required

Essential tools include a wiring harness, connectors, diagnostic tools, and installation kits. Additional hardware like shift cables and adjustment tools are also necessary for proper setup and functionality.

3.1 Wiring Harness and Connectors

The wiring harness is the backbone of the 4L60E manual shift system, connecting critical components like the TCM, solenoid pack, and sensors. A high-quality harness ensures reliable communication between these parts. It typically includes a 13-pin connector for the transmission and additional connectors for sensors like the TPS and VSS. Proper installation requires careful routing to avoid damage and interference. Original or aftermarket harnesses are available, with some kits offering pre-wired connectors for easier installation. Always use weather-sealed connectors and heat-resistant wiring to maintain durability and performance over time.

3.2 Diagnostic Tools for Troubleshooting

Essential diagnostic tools for the 4L60E manual shift wiring include a scan tool (like Tech 2) to read transmission codes and monitor real-time data. A multimeter is crucial for testing voltage, continuity, and electrical connections. Wiring diagrams are vital for tracing circuits and identifying faulty components. Additionally, a pressure test kit helps diagnose hydraulic issues, while a solenoid tester verifies solenoid functionality. These tools enable precise troubleshooting of wiring, sensors, and solenoid malfunctions, ensuring accurate repairs and optimal transmission performance. Always use high-quality tools to avoid misleading readings and ensure reliable diagnostics.

3.3 Installation Kits and Hardware

Installation kits for the 4L60E manual shift wiring include essential components like wiring harnesses, connectors, and mounting hardware. These kits often feature pre-assembled cables, brackets, and adapters to simplify the process. Specific hardware, such as shift cables and transmission levers, ensures precise control over manual shifting. Additionally, some kits include performance-enhancing components like shift kits or stand-alone controllers for improved transmission functionality. Always use high-quality, compatible hardware to ensure reliable operation and avoid potential electrical or mechanical failures during installation.

Step-by-Step Installation Guide

This section provides a detailed, sequential approach to installing the 4L60E manual shift wiring, ensuring a smooth and efficient setup process for optimal performance.

4.1 Preparing the Vehicle and Transmission

Begin by gathering all necessary tools and materials, including the wiring harness and diagnostic tools. Disconnect the battery to ensure electrical safety. Drain the transmission fluid and remove the pan and filter to access internal components. Inspect the transmission internals for any debris or wear. Install the manual shift shaft, ensuring proper alignment with the transmission case. Finally, bleed the transmission system to remove air bubbles and refill with the appropriate fluid type. This preparation ensures a smooth and safe installation process.

4.2 Removing the Old Wiring Harness

Start by disconnecting the battery to prevent any accidental electrical discharge. Locate the wiring harness connectors attached to the transmission and engine components. Use a wrench or pliers to release the connectors from their mounting clips. Gently pull the harness away from the transmission, working carefully to avoid damaging any wires or connectors. Remove any retaining brackets or clips securing the harness to the vehicle frame. Once the old harness is completely removed, inspect the area for any remaining wires or debris. This step ensures a clean slate for installing the new manual shift wiring system.

4.3 Installing the New Manual Shift Wiring

Begin by carefully unpacking the new wiring harness and components. Connect the transmission connector to the 4L60E, ensuring all pins align properly. Route the harness along the vehicle frame, securing it with provided clips or zip ties. Connect the Throttle Position Sensor (TPS) and Vehicle Speed Sensor (VSS) wires to their respective ports. Attach the Pressure Control Solenoid (PCS) and solenoid pack connectors, following the wiring diagram. Finally, connect the manual shift cable to the transmission selector, ensuring it is properly seated and adjusted. Double-check all connections before proceeding to the next step.

4.4 Connecting the Solenoid Pack

Locate the solenoid pack on the valve body and ensure it is properly seated. Align the electrical connector with the solenoid pack terminals, ensuring no pins are bent or misaligned. Secure the solenoid pack using the provided screws, tightening firmly but avoiding overtightening. Connect the wiring harness to the solenoid pack, following the wiring diagram for correct pin assignments. Double-check all connections for snugness and accuracy. Once connected, test the transmission’s shift functionality to ensure proper operation. If issues arise, verify the wiring diagram and check for any loose or damaged connections.

4.5 Routing the Manual Shift Cable

Attach the manual shift cable to the transmission’s manual shaft, securing it with the provided locking clip. Route the cable under the vehicle, ensuring it does not drag or interfere with other components. Use cable brackets or ties to secure the cable along the frame or transmission pan for proper alignment; Connect the other end of the cable to the shifter mechanism inside the vehicle. Adjust the cable tension to ensure smooth, precise shifts between gears. Test the shifting functionality to confirm proper operation and make any necessary adjustments for optimal performance.

4.6 Testing the Manual Shift Functionality

With the manual shift wiring installed, start the engine and ensure the vehicle is in neutral. Shift through all gears manually, feeling for smooth engagement and proper alignment. Check the gear indicator to confirm it matches the selected gear. Monitor the transmission’s response to manual shifts, ensuring there are no delays or harsh transitions. Test the functionality at varying speeds, including low and high ranges, to verify consistent performance. If issues arise, such as incorrect gear engagement or wiring faults, refer to the troubleshooting section for diagnostic steps. This ensures the manual shift system operates as intended.

Troubleshooting Common Issues

This section identifies and addresses common issues with the 4L60E manual shift wiring, such as faulty connections and solenoid malfunctions, providing diagnostic steps for smoother transmission operation.

5.1 Symptoms of Faulty Wiring

Faulty wiring in the 4L60E manual shift system can cause erratic shifting, delayed engagements, or complete loss of manual control. Common symptoms include the transmission stuck in a single gear, sudden slipping, or inability to shift manually. These issues often stem from worn connectors, damaged wires, or incorrect connections. Corrosion or loose terminals in the wiring harness can disrupt signal paths, leading to improper solenoid activation. If the TCM or solenoid pack malfunctions due to wiring faults, it can result in harsh or unpredictable shifting patterns. Identifying these symptoms early is crucial to prevent further damage and ensure smooth transmission operation. Always consult the wiring diagram for accurate diagnostics.

5.2 Diagnosing Solenoid Malfunctions

Solenoid malfunctions in the 4L60E manual shift system can disrupt gear changes and transmission performance. To diagnose issues, inspect the solenoid pack for signs of wear or damage. Use a multimeter to test electrical resistance and ensure proper power supply. The Pressure Control Solenoid (PCS) is critical for line pressure regulation, and its failure can cause slipping or harsh shifts. Check wiring connections to the solenoid pack and ensure clean fluid flow through the valve body. If solenoids are stuck or clogged, replace them promptly. Always refer to the wiring diagram to verify circuit integrity and signal paths for accurate troubleshooting.

5.3 Resolving Shift Delay or Harsh Shifting

Shift delays or harsh shifting in the 4L60E manual shift system often result from solenoid malfunctions or wiring issues. Check the solenoid pack for proper engagement and ensure clean fluid flow through the valve body. Verify the Throttle Position Sensor (TPS) and Vehicle Speed Sensor (VSS) are functioning correctly, as inaccurate signals can disrupt shift timing. Review the wiring diagram to identify loose or corroded connections. Clean or replace faulty wiring and connectors. If issues persist, inspect the pressure control solenoid and adjust line pressure settings. Always test shifts after repairs to confirm smooth operation.

5.4 Fixing Electrical Connectors and Wiring

To resolve electrical issues in the 4L60E manual shift wiring, inspect all connectors for corrosion or damage. Replace any faulty connectors and ensure secure connections. Use a multimeter to test wiring continuity and identify short circuits. Clean or replace frayed wires, and apply dielectric grease to prevent moisture damage. Verify the wiring harness is properly routed to avoid interference. Consult the wiring diagram to ensure all connections match the correct pinouts. If issues persist, consider installing a new wiring harness or upgrading to a stand-alone controller for improved reliability. Always test the system after repairs.

Maintenance and Upkeep

Regular maintenance ensures optimal performance of the 4L60E manual shift wiring. Clean the wiring harness, inspect connectors for corrosion, and replace worn-out components promptly. Schedule periodic diagnostic checks to identify potential issues early. Proper upkeep extends the lifespan of the electrical system and maintains smooth transmission operation.

6.1 Cleaning the Wiring Harness

Cleaning the wiring harness is essential for maintaining proper electrical connections in the 4L60E manual shift system. Use a soft-bristle brush or compressed air to remove dust and debris from the harness. For stubborn dirt or grease, apply an electronics-safe cleaner and gently wipe with a lint-free cloth. Avoid harsh chemicals or abrasive materials that could damage the wiring or insulation. Regular cleaning prevents corrosion and ensures reliable signal transmission between components. Inspect connectors for moisture or corrosion and clean or replace them as needed to maintain optimal performance.

6.2 Replacing Worn-Out Components

Replacing worn-out components in the 4L60E manual shift wiring system is crucial for maintaining reliability. Inspect the wiring harness, connectors, and shift cable for signs of wear or damage. If damaged, replace them with OEM or high-quality aftermarket parts. Use a wiring diagram to ensure correct connections. For the shift cable, align it properly with the manual shaft and secure it with the locking clip. Regularly check the solenoid pack and pressure control solenoid for any corrosion or malfunction. Replace faulty sensors like the TPS or VSS to ensure smooth shifting and proper transmission control.

6.3 Regular Diagnostic Checks

Regular diagnostic checks are essential to ensure the 4L60E manual shift wiring system operates smoothly. Start by inspecting the wiring harness and connectors for any signs of damage or corrosion. Use a multimeter to verify voltage and continuity in critical circuits. Check the transmission control module (TCM) for any stored trouble codes using a diagnostic tool. Monitor the throttle position sensor (TPS) and vehicle speed sensor (VSS) for accurate readings. Test the solenoid pack and pressure control solenoid for proper function. Regular checks help identify and address issues before they escalate, ensuring reliable manual shift performance.

Advanced Modifications for Performance

Advanced modifications enhance the 4L60E’s performance, such as installing a shift kit for faster engagements or upgrading to a stand-alone controller for precise manual control.

7.1 Installing a Shift Kit for Improved Performance

A shift kit enhances the 4L60E’s performance by modifying hydraulic circuits to improve shift timing and firmness. This upgrade reduces slippage and prolongs transmission life.

The kit includes components like accumulators and springs to optimize pressure control. Installation requires careful calibration of the solenoid pack and valve body.

With a shift kit, drivers experience crisper shifts, better throttle response, and increased durability under heavy loads. It’s ideal for high-performance applications or towing scenarios.

7.2 Upgrading to a Stand-Alone Controller

Upgrading to a stand-alone controller enhances control over the 4L60E transmission by bypassing the vehicle’s PCM. This allows for precise tuning of shift points, line pressure, and torque converter engagement.

A stand-alone controller, such as the AMPSTOE NCR60E, simplifies wiring by eliminating complex factory connections. It enables manual shift functionality and improves performance in racing or high-stress applications.

This upgrade is ideal for enthusiasts seeking full control over their transmission’s behavior, ensuring faster and firmer shifts for optimal power delivery.

7.3 Adding a Sport Mode or Manual Shift Button

Adding a sport mode or manual shift button enhances driver control over the 4L60E transmission. This modification allows for on-demand shifts, improving performance in racing or sport driving scenarios.

The process involves wiring a momentary switch to the stand-alone controller, connecting the Dark Blue down-shift wire and Light Blue up-shift wire with a 680 Ohm resistor. This setup enables quick, manual gear changes without relying on automatic functions.

The sport mode feature can be activated via a separate button, providing faster shift responses and increased line pressure for optimal power delivery.

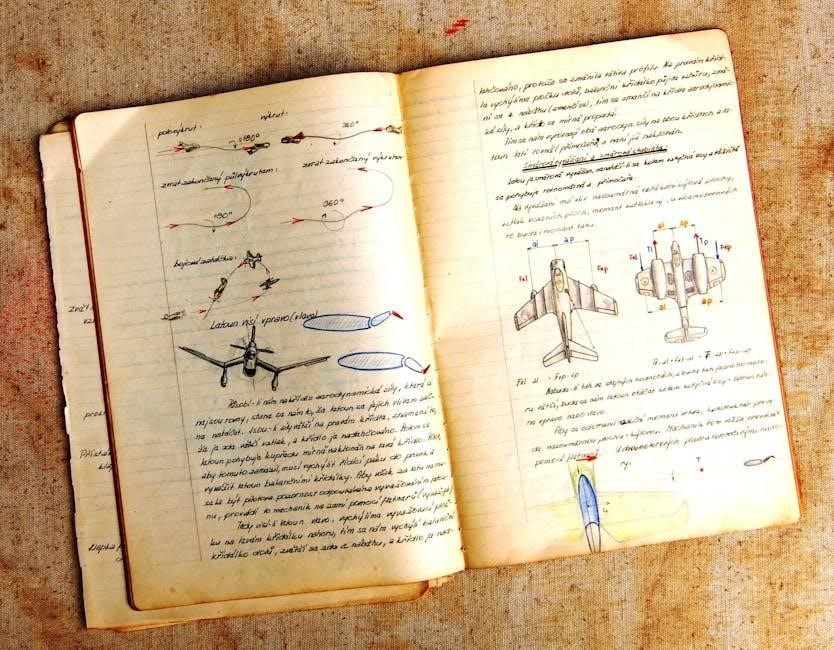

Wiring Diagram Explanation

A wiring diagram provides a visual representation of the 4L60E’s electrical connections, showcasing components, signal paths, and their interactions. It aids in diagnosing issues and installing manual shift systems.

8.1 Understanding the Pinout Layout

The pinout layout is fundamental for identifying connections in the 4L60E wiring diagram. It details the specific functions of each pin in the transmission’s connectors, ensuring proper installation. Key pins, such as Pin 14 for the down-shift button, are highlighted to simplify manual shift conversions. The layout also specifies resistor requirements, like the 680 Ohm resistor for switch connections, ensuring signal accuracy. This visual guide aids in troubleshooting and installing components like the Dark Blue wire for down-shift functionality. Proper understanding of the pinout layout is crucial for maintaining transmission performance and diagnosing electrical issues effectively.

8.2 Interpreting the Wiring Schematic

The wiring schematic for the 4L60E manual shift conversion provides a detailed visual representation of electrical connections. It outlines the flow of signals between components like the TPS, VSS, and solenoid pack. Color-coded wires, such as the Dark Blue down-shift wire, are clearly marked to simplify installation. Symbols and labels indicate resistor values, connector pins, and switch placements. By interpreting the schematic, users can identify key signal paths and troubleshoot issues efficiently. This guide ensures proper connections for manual shift functionality, enabling smooth transitions and optimal transmission performance. Accurate interpretation is critical for reliable operation and diagnostics.

8.3 Identifying Key Signal Paths

The wiring diagram highlights essential signal paths for the 4L60E manual shift system. The Dark Blue wire (Pin 14) connects to the down-shift button, while the Light Blue wire handles up-shift signals. These paths interact with the TPS and VSS sensors, providing critical data to the TCM. The TCM processes these signals to control solenoid activation, ensuring smooth gear transitions. Proper identification of these paths is vital for diagnosing issues like delayed or harsh shifting; By tracing these connections, users can verify wiring integrity and ensure reliable transmission performance. This step is crucial for both installation and troubleshooting.

Safety Precautions

Always wear protective gear and disconnect the battery before working on electrical systems. Handle high-pressure components with care to avoid injury. Use appropriate tools and follow proper procedures to ensure safety.

9.1 Working with Electrical Systems Safely

When working with electrical systems, disconnect the battery to prevent accidental power surges or shocks. Always wear protective gear, including gloves and safety glasses. Avoid wearing jewelry that could conduct electricity; Ground the vehicle properly to prevent static discharge, which can damage sensitive components. Use insulated tools to handle wiring and connectors. Never test circuits with the ignition on, as this can cause short circuits. Consult the wiring diagram to identify live wires and avoid misconnections. By following these precautions, you ensure a safe working environment and protect both yourself and your vehicle’s electrical systems.

9.2 Handling High-Pressure Components

When working with high-pressure components like the solenoid pack or hydraulic lines, ensure all systems are depressurized before disconnection. Wear protective eyewear and gloves to prevent injury from potential fluid leaks. Use properly rated tools to avoid damaging fittings or lines. Never force connections; consult the wiring diagram or manual for correct procedures. If installing components like the Pressure Control Solenoid (PCS), follow torque specifications to prevent damage. Always test for leaks after reassembly to ensure system integrity. Proper handling ensures safety and prevents costly repairs.

This comprehensive guide provides detailed steps for installing and troubleshooting the 4L60E manual shift wiring, ensuring smooth transmission control and enhanced performance for your vehicle.

10.1 Summary of Key Points

The 4L60E manual shift wiring diagram guide covers essential components like the TCM, solenoid pack, and sensors. It outlines installation steps, troubleshooting tips, and maintenance practices. Proper wiring connections, shift kit upgrades, and sport mode additions enhance performance. Regular diagnostics and component replacements ensure longevity. This comprehensive resource helps users achieve precise control over their transmission, ensuring smooth shifting and optimal vehicle performance.

10.2 Final Tips for Successful Installation

For a seamless 4L60E manual shift wiring installation, ensure all connections are secure and properly grounded. Reference the wiring diagram to avoid misconnections. Use high-quality tools and components to prevent damage. Test the system thoroughly before driving to identify any issues early. Regular maintenance, such as cleaning the wiring harness and replacing worn parts, will ensure long-term performance. If unsure, consult a professional or detailed repair manual for guidance. Proper installation and care will enhance your transmission’s reliability and shifting precision.